Food cold chain

Eco-smart ventilated packaging for fresh fruit using virtual cold chains

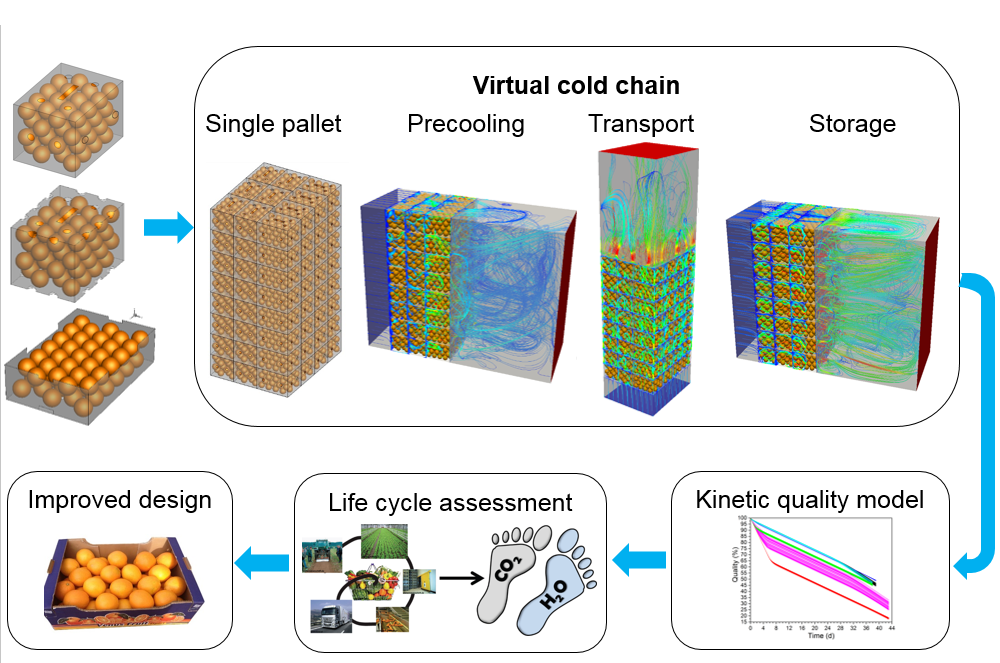

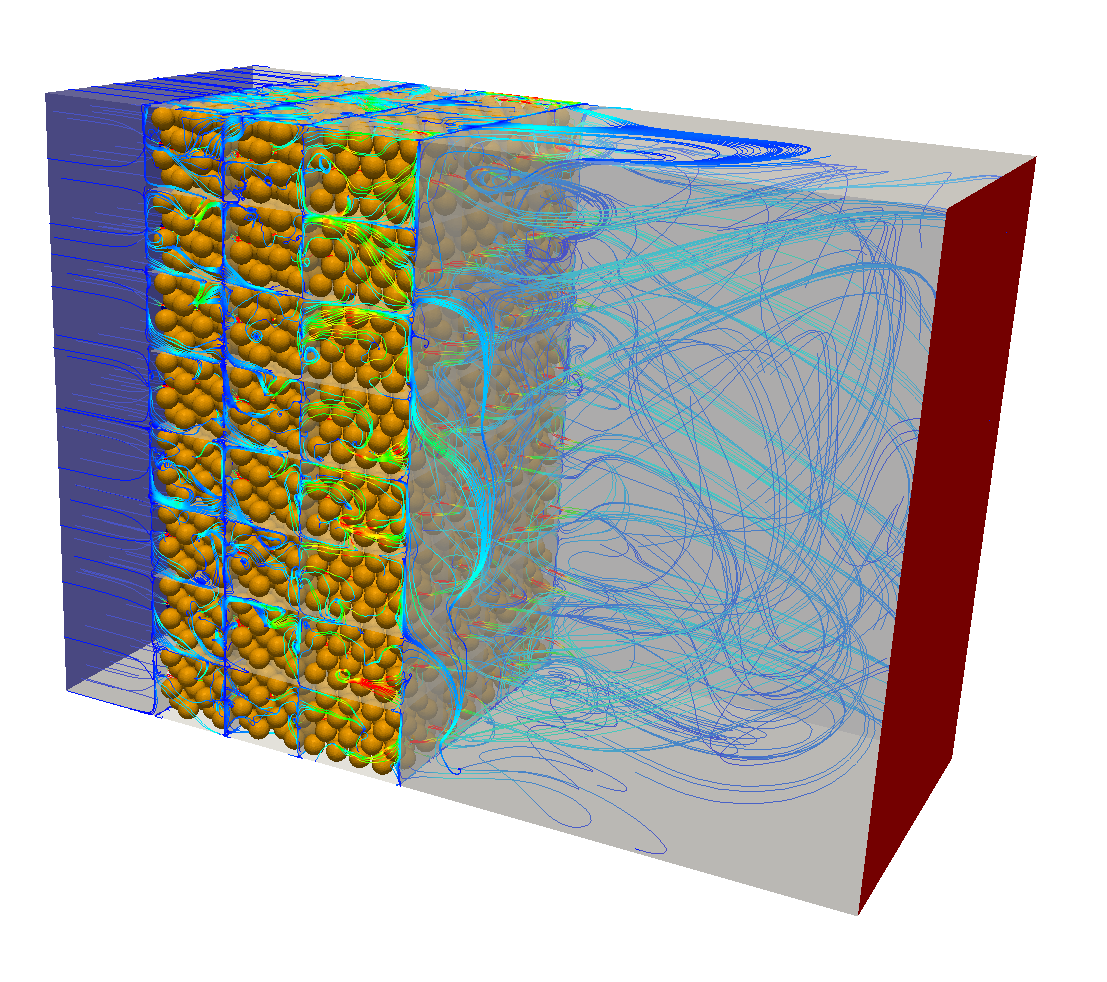

An important share of the food losses, energy consumption and carbon footprint in the fresh fruit and vegetables supply chain is embedded within postharvest unit operations such as precooling, refrigerated transport and storage. Improving ventilated packaging is an efficient way to increase product quality and shelf life by better and more uniform cooling throughout the cold chain. Packaging also helps in reducing the energy use of mechanical ventilation systems by altering the airflow resistance. The complex role of packaging solutions in the fresh produce supply chain is still not fully understood. The project combines virtual tracking of individual fruit throughout the cold chain unit operations with life cycle assessment as a novel approach to improve the food cold chain, by reducing product losses and environmental impact.

This project is led by Dr. Thijs Defraeye. Collaborations. This project is a collaboration between the Chair of Building Physics (Dr. Defraeye, Prof. Carmeliet) and the Chair of Ecological Systems Design (Prof. Hellweg) at ETH Zurich. External partners are the University of Stellenbosch (Prof. Opara) and Citrus Research International (Dr. Cronje) in South Africa. This postdoctoral project is funded via Coop Research Program of the World Food System Center of ETH Zurich