Wicking in textile

Moisture in textiles can affect the wearer’s comfort and performance. The phenomenon of moisture uptake in textiles due to capillary action is called wicking. Wicking is a multi-scale phenomenon. At the yarn scale there is wetting of the fibers and creation of a thin film, while the presence of nearby fibers enables meniscus formation where capillary forces drive the further imbibition of the yarn. Yarn characteristics such as wettability, twisting level and hygroscopic behavior can all influence the wicking at the yarn scale. Yarns are assembled in a fabric structure (e.g. woven or knit). At the fabric scale parameters such as structure, direction and pick density define the inter-yarn geometry and impact the overall wicking behavior.

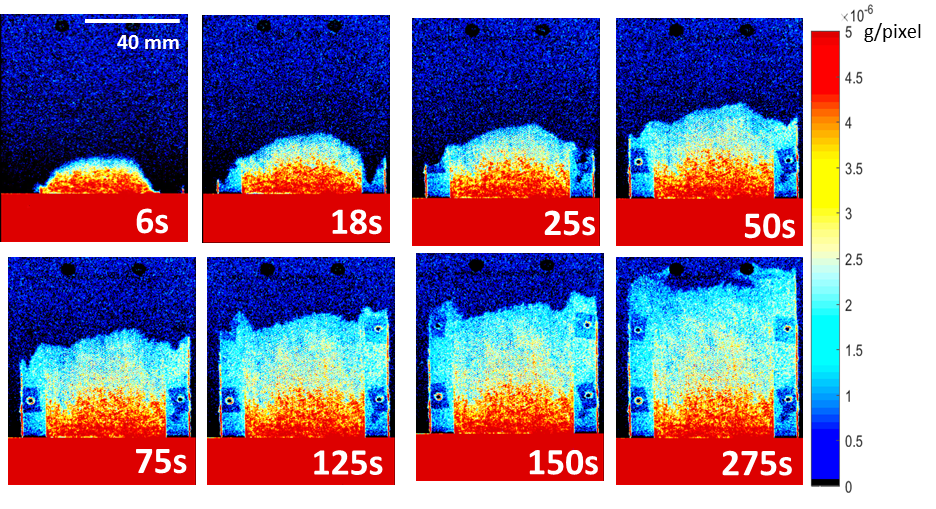

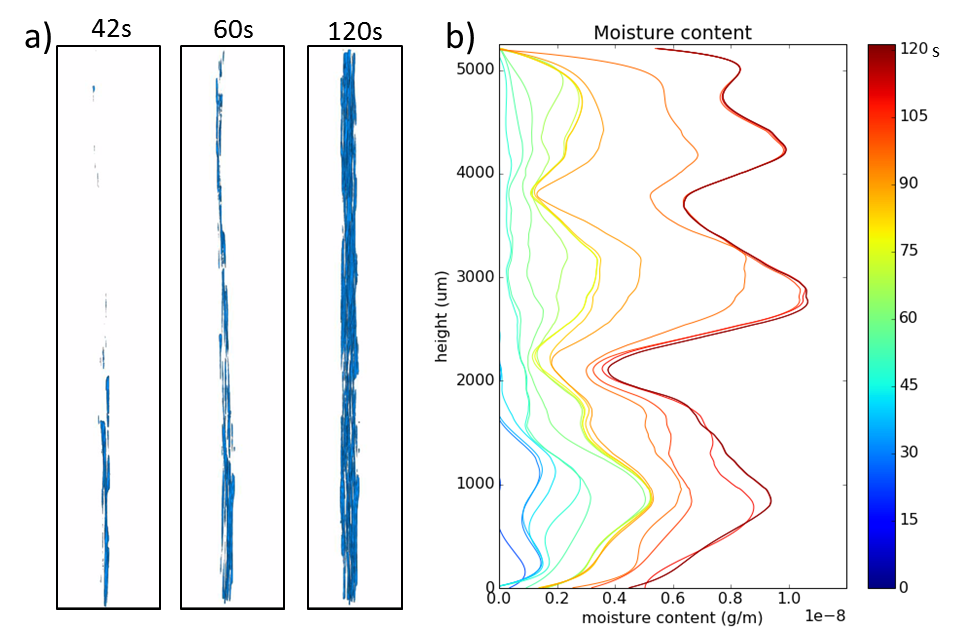

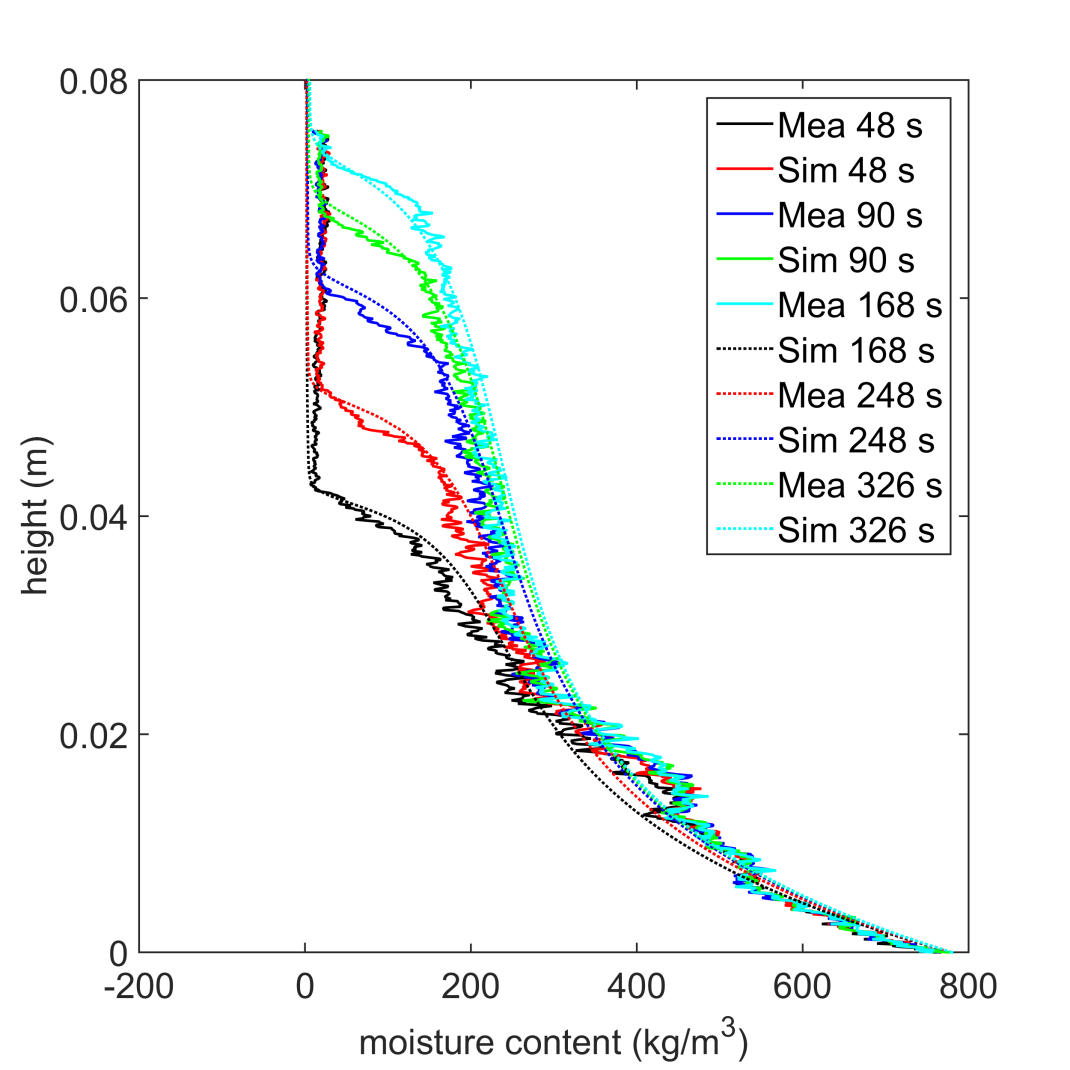

In this project we investigate wicking at both yarn and fabric scale, experimentally and numerically. We apply advanced imaging techniques such as neutron radiography and synchrotron-based X-ray phase-contrast tomography to obtain the time resolved 2D and 3D distribution of moisture on yarns and fabrics. We investigate yarns and fabrics of different materials and parameters (e.g. twisting level, fabric structure etc.)

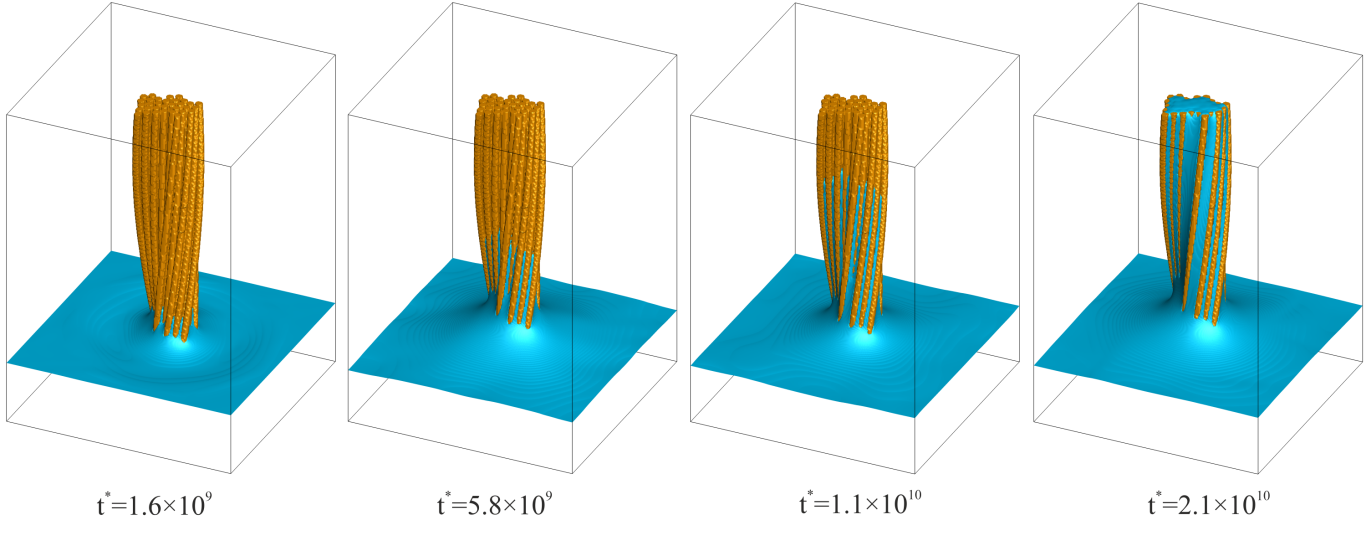

Modeling is realized either using continuum approaches for wicking in fabrics or Lattice-Bolzmann simulations at the yarn scale.

Lattice-Boltzmann

A textile is an assembly of yarns containing fibers. Yarns can include between 1 and around 100 fibers of a few microns to one millimeter diameter each. Transport of water through textile play a very important role in deciding comfort, dyeing of textile fabrics, liquid filtration and so on. The wetting of highly flexible textile leads to a complex configuration of the liquid phase within the high porosity medium. Thus, the modelling and prediction of this behavior is very challenging. Continuum approaches have been developed with proper input from measurement, however their use as predictive toll is limited. A much more competent approach is required to capture and investigate the phenomena in the full intricacy. Here in our lab to first understand and capture the physics at the microscale, we propose the lattice Boltzmann method as the numerical tool for simulations of wicking through twisted yarns.

Lattice Boltzmann method takes a mesoscopic approach that could be imagined to lie in between the micro and macro worlds. Based on the kinetic lattice Boltzmann equation, particle interactions are directly implemented, while the movement of those particles is confined to a discrete lattice. This makes the LBM very useful in modeling interfacial dynamics and multiphase flows without the need for complex interface tracking algorithms resulting in less computational cost. Moreover, the LBM has particular significance for porous media because of its ability to easily incorporate the geometrically complex boundary conditions relative to continuum modeling approaches, which makes possible the simulation of multiphase flows in porous media with the realistic complex three-dimensional geometries.